Fibre optic network up to date again thanks to APS and Blowtube system

In Lendelede, West Flanders, the food company Volys has been working hard since 1946. The specialist in versatile chicken and turkey products has been recording good growth figures for a number of years now, and this has also had an impact on the company's installations. APS, a subsidiary of ATS Group, was recently involved in two projects: the installation of a new fibre-optic backbone for security and an update of the data network.

| Customer: | Volys |

| Expertise: | Network infrastructure, data cabling, Air Blown Fiber, access control |

| Location: | Lendelede |

| Implementation: | 2018 |

In the food industry, very specific standards are in force. One of them is BRC7, in which a chapter is called Food Defence, which requires, among other things, that your premises are properly locked. This way, you can know who is present in the company at all times. For that reason, APS installed an installation with access control for vehicles and persons, in combination with camera surveillance around the outer perimeter. But to connect all these components and cameras, a glass fibre network was needed around the company.

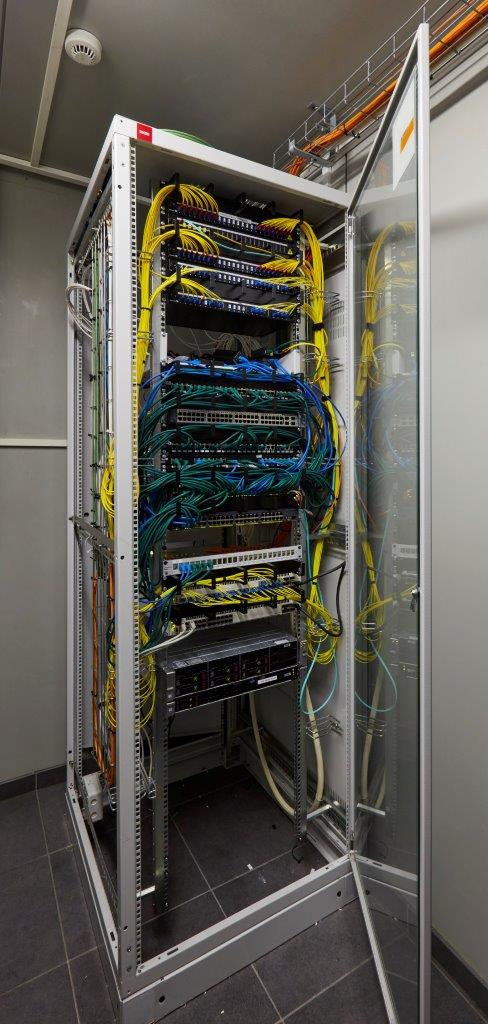

APS was also responsible for updating the company's internal data network. The installation had become outdated over the years and had a chaotic structure with all the associated problems: the structure was unclear, documentation was lacking, data cabinets were placed in haphazard locations, etc. In addition, more and more things were added over the years, which meant that nobody was really fully aware of how the installation worked.

When the complexity of the installation became clear, APS proposed not to work with a fixed type of glass fibre cable but with a Blowtube system. You can easily and very flexibly create branches with this. APS then constructed a customised plan for both the outer and inner perimeter. First, a new cable route was constructed. The old cable routes were overcrowded and there was a risk of cutting the cables here and there if additional cables were pulled. After these adjustments, the necessary connections were made and the fibre-optic cables could be blown.

Production hardly suffered at all during the system conversion, which was extremely important for the customer. Both the perimeter and the internal data network are now compliant and ready for the future.